Quando si tratta di incidere il metallo, precisione, energia, e l'affidabilità sono fondamentali. Incisori laser fibra are specifically designed to meet these demands, making them the go-to choice for professionals and enthusiasts alike. If you’re looking to explore the world of metal engraving, this guide will cover everything you need to know to select the best fiber laser engraver for metal and optimize your process for superior results.

Sommario

1. Understanding the Advantages of Fiber Laser Engravers for Metal

Fiber laser engravers have revolutionized metal engraving with their ability to produce high-quality marks on various metals, compreso l'acciaio inossidabile, alluminio, ottone, rame, e titanio. Unlike other types of lasers, come i laser a CO2, fiber lasers are specifically tuned for metal engraving. They offer:

- Alta precisione: Fiber lasers generate a focused beam with a small spot size, enabling detailed and intricate engravings.

- Durabilità: The marks made by fiber lasers are resistant to wear, heat, and corrosion, making them ideal for industrial applications.

- Velocità ed efficienza: With high processing speeds and minimal maintenance, fiber lasers allow for rapid production without sacrificing quality.

- Bassi costi operativi: Laser a fibra have long lifespans and low energy consumption, making them cost-effective over time.

2. Choosing the Right Power Level

The power level of your fiber laser engraver significantly affects the quality and depth of the engraving. Lower power (per esempio., 20W) is suitable for surface marking and engraving on thin metals, while higher power (per esempio., 60W) is necessary for deeper engravings and cutting thicker materials. When selecting a fiber laser engraver for metal, prendere in considerazione:

- Material Thickness: Higher power is required for thicker metals.

- Desired Engraving Depth: Deeper engravings necessitate more power.

- Speed Requirements: Higher power allows for faster engraving without compromising quality.

Per esempio, IL ComMarker B4-60W Fiber Laser Engraver is ideal for heavy-duty applications, offering the power needed for deep metal engravings and cutting.

3. Exploring Different Types of Metal Engraving

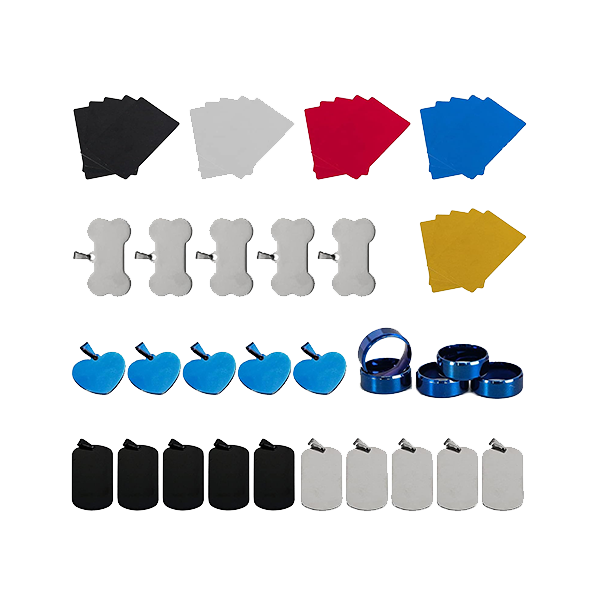

Fiber laser engravers can handle various types of metal engraving, each with its specific applications:

- Annealing: This process involves heating the metal surface to create a mark without removing material, ideal for stainless steel.

- Ablation: Removing the top layer of metal to expose the underlying material, often used for creating contrast on anodized aluminum.

- Etching: Shallow marking, typically used for identification numbers, loghi, and barcodes.

- Incisione profonda: Removing significant material to create three-dimensional effects, commonly used in mold making and heavy-duty applications.

Each method has its unique advantages, and understanding which technique suits your application will help you achieve the best results.

4. Optimizing Settings for Different Metals

Different metals require different laser settings to achieve the best results. Factors such as power, velocità, frequenza, and focus all play a role in the quality of the engraving:

- Acciaio inossidabile: Lower speeds and higher power settings are typically used to achieve deep, permanent marks.

- Alluminio: Higher speeds and lower power are often preferred to avoid excessive material removal.

- Ottone e Rame: These materials are highly reflective, so lower power and slower speeds are recommended to prevent overheating.

Experimenting with these settings and adjusting them based on the specific metal and desired outcome is crucial for perfecting your engraving process.

5. Importance of Cooling and Ventilation

Metal engraving generates significant heat, which can affect both the engraver and the workpiece. Proper cooling and ventilation are essential to maintain the integrity of the engravings and ensure the longevity of the machine:

- Sistemi di raffreddamento: Fiber lasers often come with built-in cooling systems to dissipate heat during operation.

- Ventilation: Adequate ventilation is necessary to remove fumes and particles generated during engraving, especially with metals that produce hazardous byproducts.

Investing in a high-quality ventilation system will not only protect your health but also improve the quality of your engravings.

6. Software Considerations for Precision Engraving

The software used to control your fiber laser engraver plays a significant role in the precision and ease of the engraving process. Look for software that offers:

- Compatibilità: Ensure that the software is compatible with your machine and supports the file formats you commonly use.

- Interfaccia intuitiva: Intuitive controls and easy-to-understand features make it easier to set up and execute engravings.

- Funzionalità avanzate: Options like automatic focus, power control, and preview modes can enhance the precision and efficiency of your work.

ComMarker’s B4 series, Per esempio, is compatible with popular software like LightBurn and EZCAD2, offering both ease of use and powerful customization options.

7. Safety Precautions When Engraving Metal

Safety is paramount when working with powerful laser engravers. Metal engraving can generate harmful fumes, intense light, and hot surfaces. To ensure safe operation:

- Protective Gear: Always wear appropriate safety glasses to protect your eyes from laser radiation.

- Fume Extraction: Use a fume extractor to remove harmful particles from the air.

- Laser Enclosure: Consider using a machine with a built-in enclosure or adding one to prevent accidental exposure to the laser beam.

Following these safety guidelines will help you avoid accidents and maintain a safe working environment.

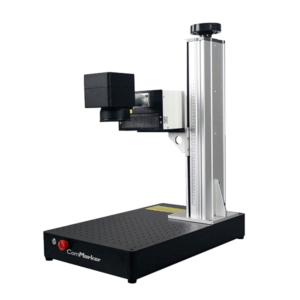

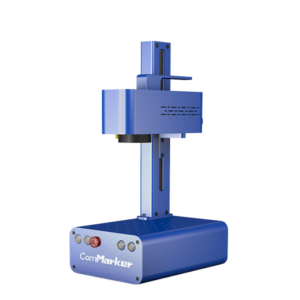

8. Why ComMarker B4 Series is Ideal for Metal Engraving

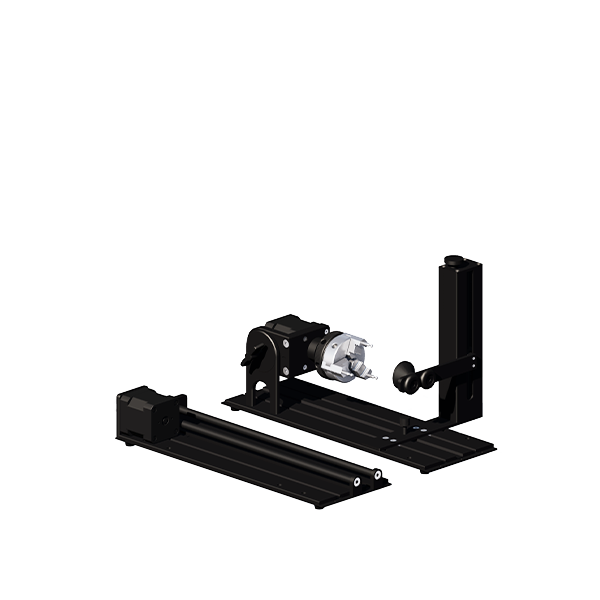

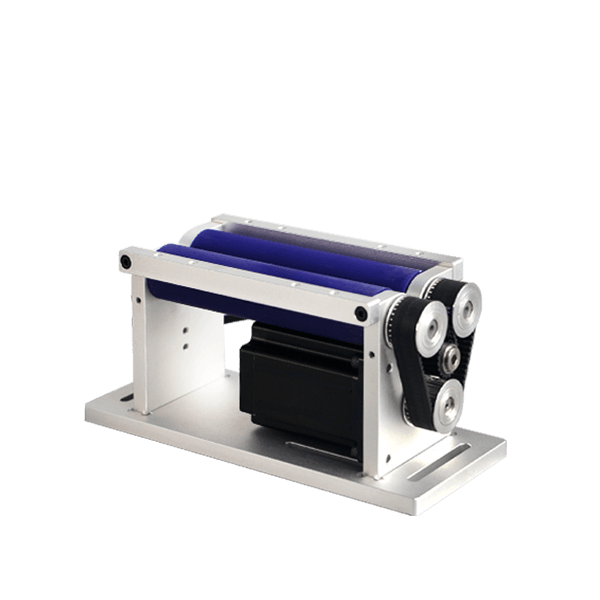

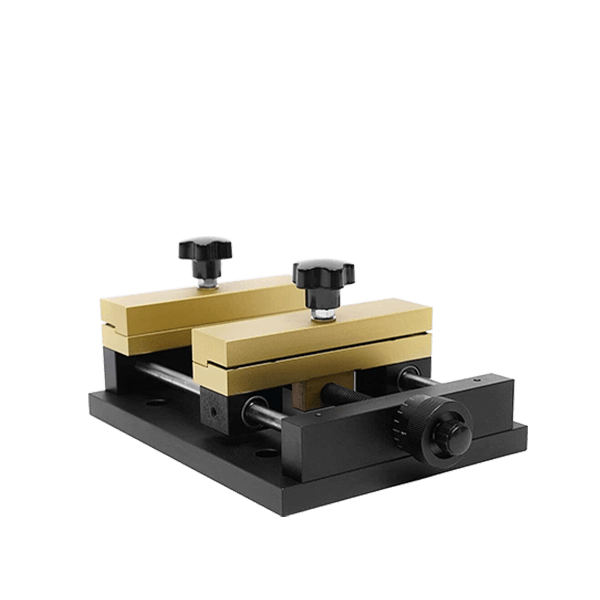

ComMarker’s B4 Series fiber laser engravers are specifically designed for metal engraving, offering unmatched precision, energia, e versatilità. With features like electric lifting for precise focusing, wide software compatibility, and industrial-grade components, the B4 series is an excellent choice for both beginners and experienced professionals.

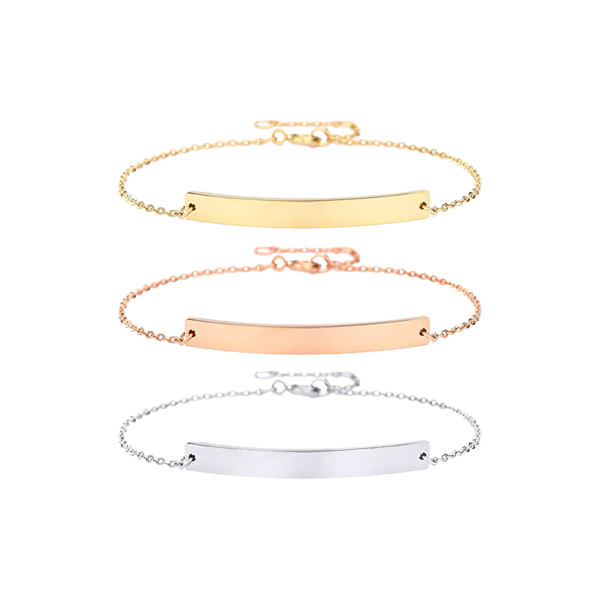

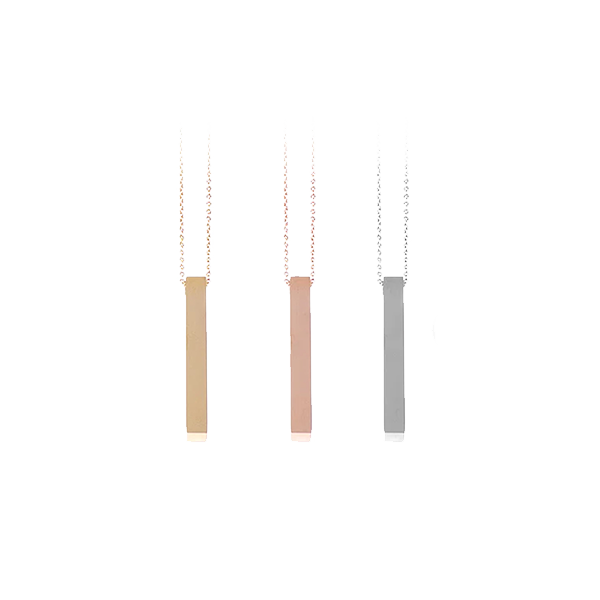

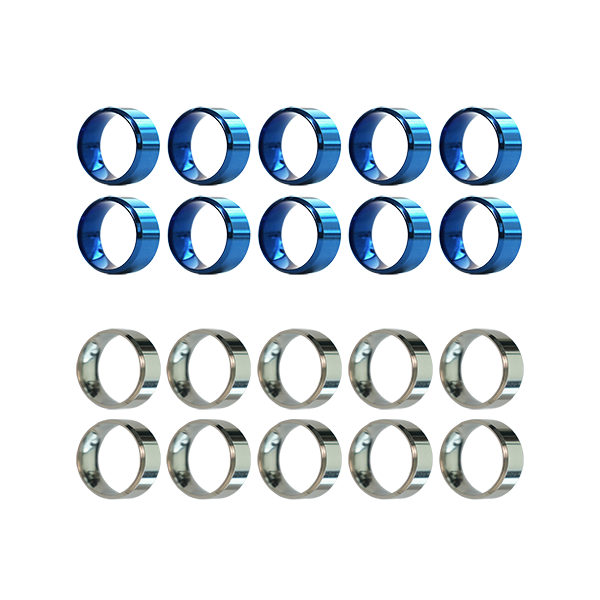

Whether you’re engraving intricate designs on jewelry or creating deep engravings on industrial parts, the ComMarker B4 series delivers consistent, high-quality results.

Macchina per marcatura laser a fibra ComMarker B4 60W JPT MOPA

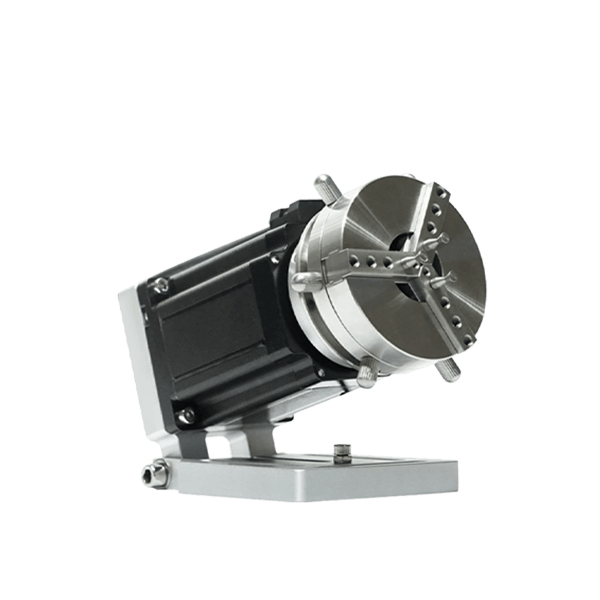

Portatile & Conveniente: La macchina per marcatura laser a fibra B4 MOPA 60W pesa solo 22 kg; dimensioni compatte entro 336*555*635 mm. Sollevamento elettrico: Motore di sollevamento nascosto incorporato per una messa a fuoco precisa. Marcatura a colori & Abilità di taglio eccellente: Possibilità di incisione a colori su acciaio inossidabile, bianco e nero su alluminio, e taglio di metalli fino a 2 mm di spessore con una precisione di 0,01 mm. Spazioso…

FAQs about Fiber Laser Engraving Metal

1. Can You Engrave Metal with a Fiber Laser?

SÌ, you can engrave metal with a fiber laser. Infatti, fiber lasers are one of the most effective tools for engraving a wide variety of metals, compreso l'acciaio inossidabile, alluminio, ottone, rame, e altro ancora. The focused beam of a fiber laser creates detailed, high-contrast marks that are both durable and resistant to wear. Fiber lasers can perform different types of metal engraving, such as annealing, acquaforte, and deep engraving, making them versatile tools for various applications, from industrial marking to personalized items.

2. What Can a Fiber Laser Not Engrave?

While fiber lasers are highly effective for metal and some plastics, they have limitations when it comes to certain materials:

- Transparent Materials: Fiber lasers struggle to engrave clear materials like glass or acrylic because the laser light passes through them without being absorbed.

- Materiali organici: Fiber lasers are not well-suited for engraving organic materials like wood, pelle, or paper. CO2 lasers are better for these types of materials.

- Highly Reflective Metals: Although fiber lasers can engrave most metals, extremely reflective metals like silver and gold might require special settings or surface treatment to avoid reflecting the laser beam and damaging the equipment.

3. What Are the Limitations of Laser Engraving?

Incisione laser, while powerful and precise, does come with some limitations:

- Compatibilità dei materiali: Not all materials can be engraved effectively. Per esempio, certain plastics may emit harmful fumes, and transparent or highly reflective materials pose challenges.

- Depth Limitations: Achieving significant engraving depth can be time-consuming, and some materials may not allow for deep engraving without compromising structural integrity.

- Size Restrictions: The work area of the laser machine limits the size of the objects you can engrave. Larger items may need to be engraved in sections or require specialized equipment.

- Surface Preparation: Certain materials might need pre-treatment (per esempio., applying a coating or paint) to achieve the desired engraving result, which adds extra steps to the process.

4. Will a Fiber Laser Cut Metal?

SÌ, a fiber laser can cut metal, but it depends on the power of the laser and the thickness of the metal. High-power fiber lasers, like a 60W or higher, are capable of cutting through thin sheets of metal, come l'acciaio inossidabile, alluminio, e ottone, with precision. Tuttavia, for thicker metals, more powerful industrial fiber lasers (often in the range of hundreds to thousands of watts) are required. While the ComMarker B4-60W Fiber Laser Engraver can cut metal up to 2 mm di spessore, more substantial cutting tasks will need more powerful equipment.

5. What Is the Wavelength of a Metal Cutting Fiber Laser?

The wavelength of a fiber laser typically used for cutting metal is around 1,060 nanometri (nm). This wavelength is ideal for metals because it is efficiently absorbed by metallic surfaces, allowing the laser to cut or engrave the material effectively. This is in contrast to CO2 lasers, which have a wavelength of approximately 10,600 nm and are more suitable for non-metal materials. The shorter wavelength of fiber lasers makes them particularly well-suited for metalworking applications.