Hva er UV-lasergravering?

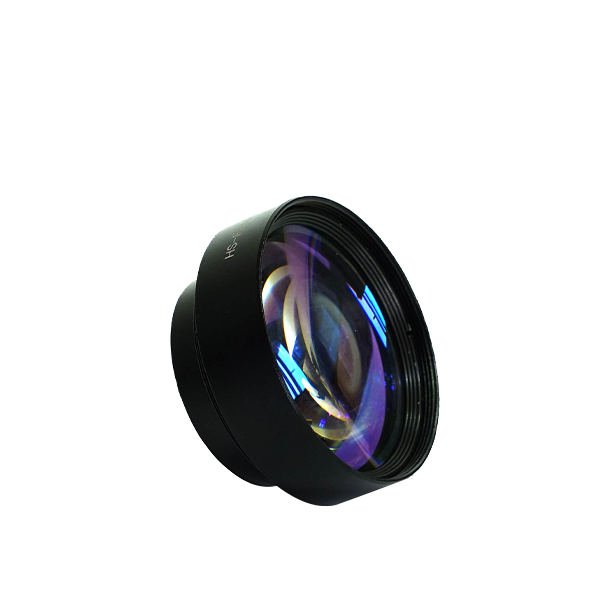

UV laser engraving is a process that uses ultraviolet laser light to etch or mark surfaces. De UV laser operates at a wavelength of 355 nm, enabling high precision and fine detail in the engraving. It’s ideal for materials sensitive to heat, such as plastics, glass, og keramikk, due to its low thermal impact.

Does UV Laser Engraving Really Work?

Ja, UV laser engraving is highly effective. It uses a UV laser beam to precisely remove material from the surface of an object, creating detailed and intricate designs. Its shorter wavelength allows for high precision and minimal thermal impact, making it suitable for delicate materials like plastics, glass, and even certain metals.

What Can You Do with a UV Laser?

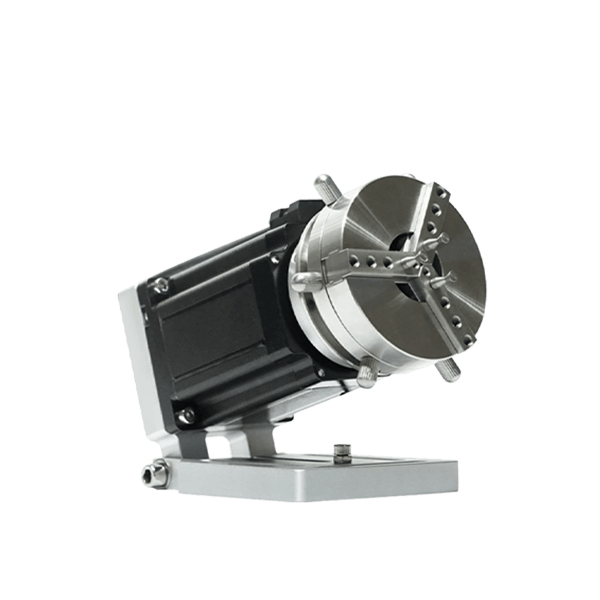

- Engraving intricate designs on plastics, glass, keramikk, and metals.

- Marking electronic components and circuit boards.

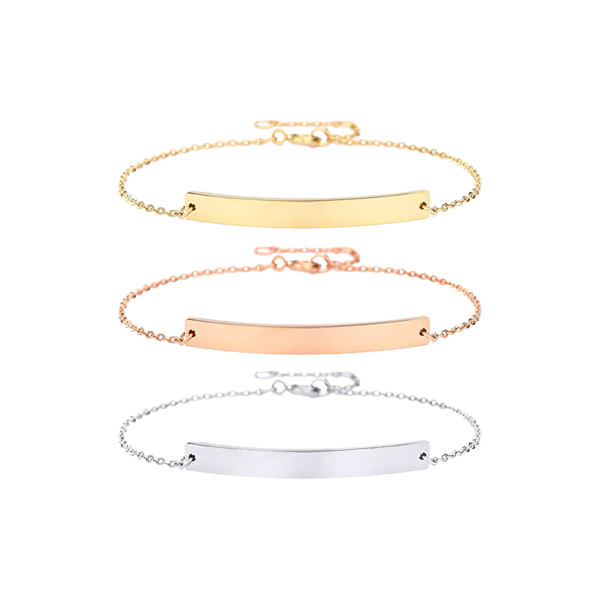

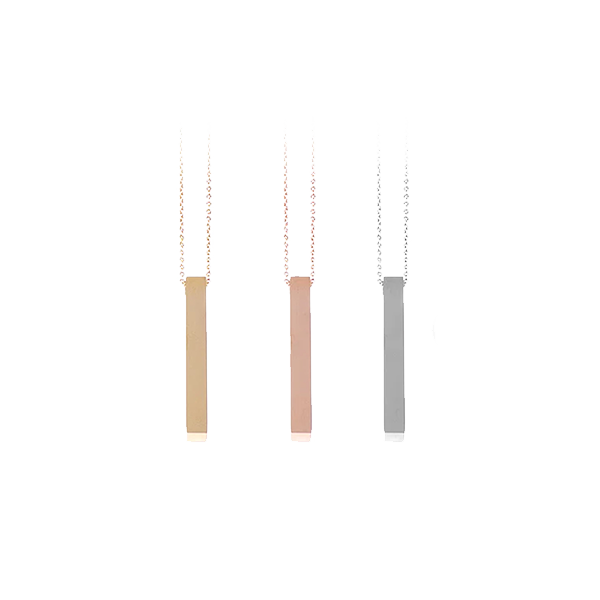

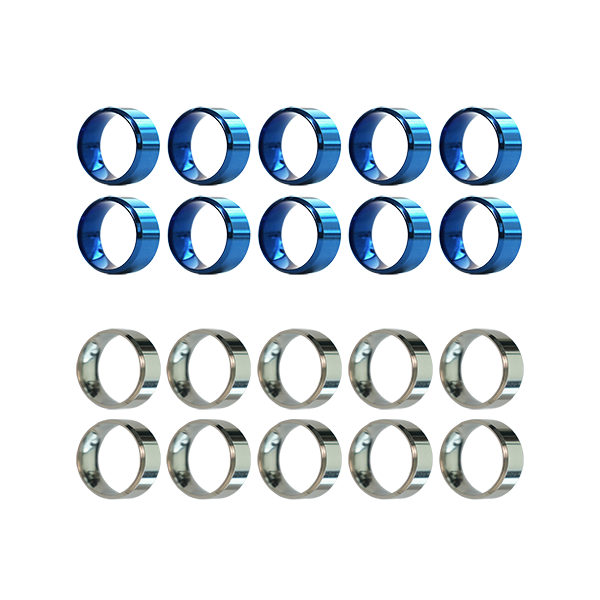

- Personalizing items like jewelry, penner, and gifts.

- Creating barcodes, serienummer, and QR codes on products.

- Producing high-contrast, permanent markings on sensitive materials.

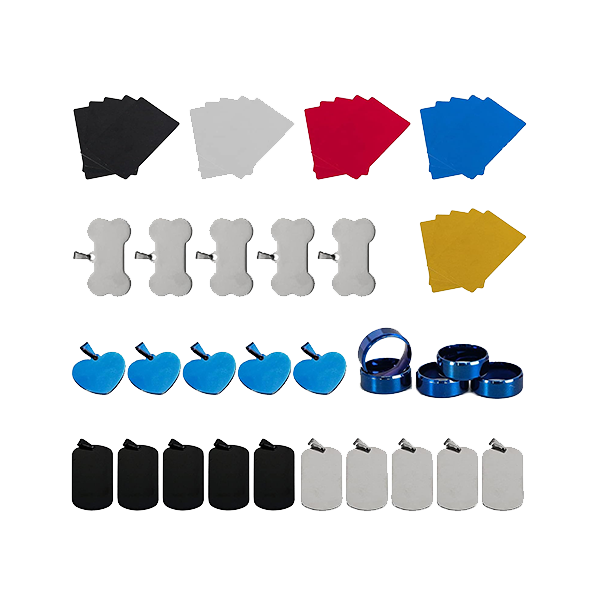

What Types of Materials Can UV Laser Engraving Handle?

UV laser engraving is versatile and can handle a variety of materials, including:

- Plast

- Glass

- Ceramics

- Metaller (with certain coatings)

- Fabrics

What Industries Commonly Use UV Laser Engraving?

UV laser engraving is used across various industries such as:

- Electronics: Marking circuit boards and components.

- Automotive: Engraving plastic parts and components.

- Medisinsk utstyr: Marking surgical instruments and devices.

- Jewelry: Personalizing metal and plastic items.

- Packaging: Creating barcodes and QR codes.

How Does UV Laser Engraving Compare to Traditional Engraving Methods?

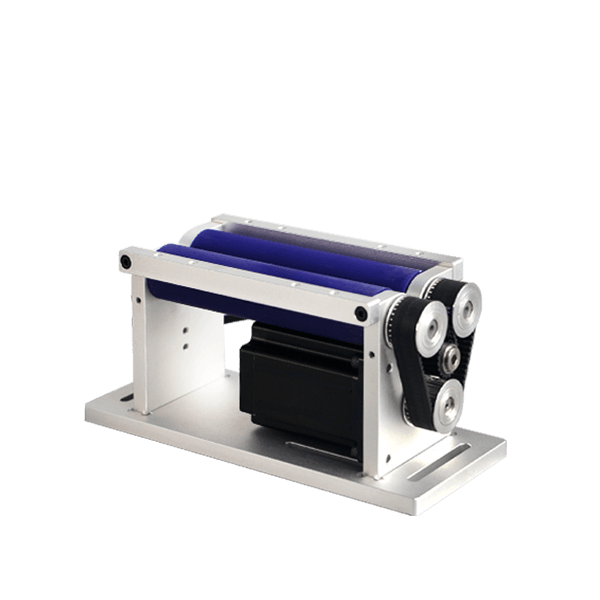

- Presisjon: UV laser engraving offers higher precision and finer detail.

- Thermal Impact: UV laser has minimal thermal impact, making it suitable for heat-sensitive materials.

- Non-contact Process: Reduces wear and tear on materials.

- Hastighet: Faster engraving compared to traditional methods.

What is the Difference Between UV Printing and Engraving?

UV printing involves applying UV-curable ink to a surface and then curing it with UV light, creating a durable and colorful print. In contrast, UV laser engraving uses a UV laser to physically remove material from the surface to create a design or mark. Printing adds material to the surface, while engraving removes it.

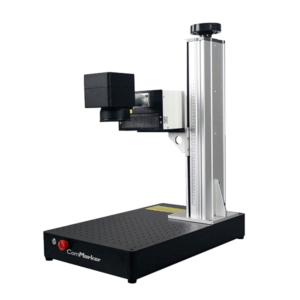

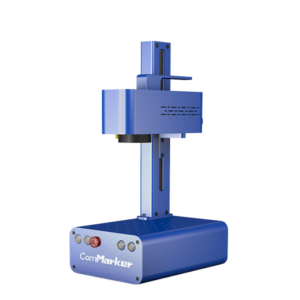

Is a Fiber Laser Engraver Better Than a UV Laser Engraver?

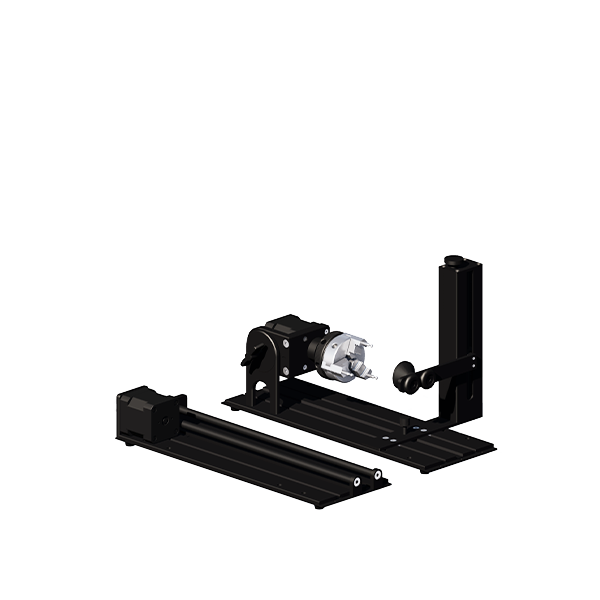

The choice between a fiber laser and a UV laser engraver depends on the application:

- Fiberlasergravør: Best for metals and hard materials, offering high speed and deep engraving.

- UV lasergraver: Ideal for delicate materials like plastics, glass, og keramikk, providing high precision with minimal thermal damage.

What are the Disadvantages of UV Laser Engraving?

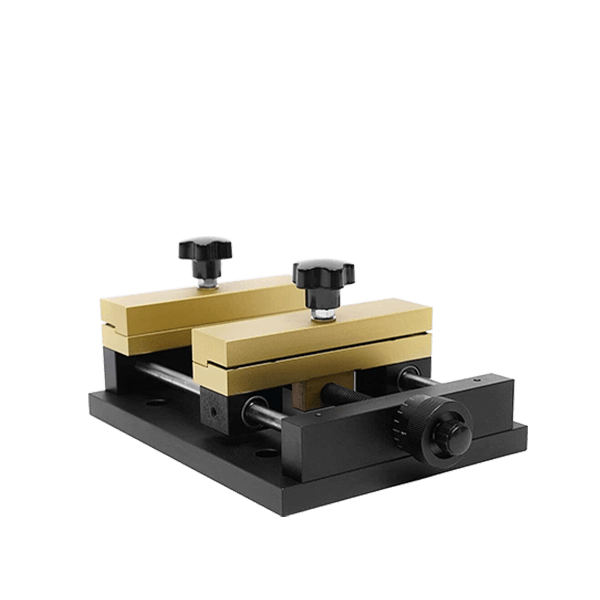

- Cost: UV laser systems can be expensive.

- Material Limitation: Less effective on some metals and thicker materials.

- Maintenance: Requires regular upkeep for optimal performance.

How Long Does UV lasergravering Last?

UV laser engravings are generally permanent and can last a lifetime under normal conditions. They are resistant to wear, kjemikalier, and UV radiation, making them ideal for long-term applications.

Ofte stilte spørsmål

Q: What types of materials can UV laser engraving handle?

EN: UV laser engraving is versatile and can handle plastics, glass, keramikk, metaller (with certain coatings), and fabrics.

Q: What industries commonly use UV laser engraving?

EN: UV laser engraving is widely used in electronics, bilindustrien, medical devices, smykker, and packaging industries.

Q: How does UV laser engraving compare to traditional engraving methods?

EN: UV laser engraving offers higher precision, minimal termisk påvirkning, faster processing, and is a non-contact method, reducing wear and tear on materials.